Choosing the Best Defoamers for Your Manufacturing Line

Choosing the Best Defoamers for Your Manufacturing Line

Blog Article

Exactly How Defoamers Improve Effectiveness in Production and Production

Understanding Defoamers

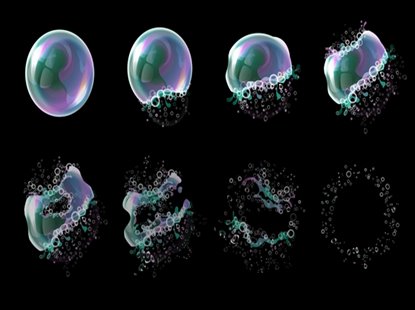

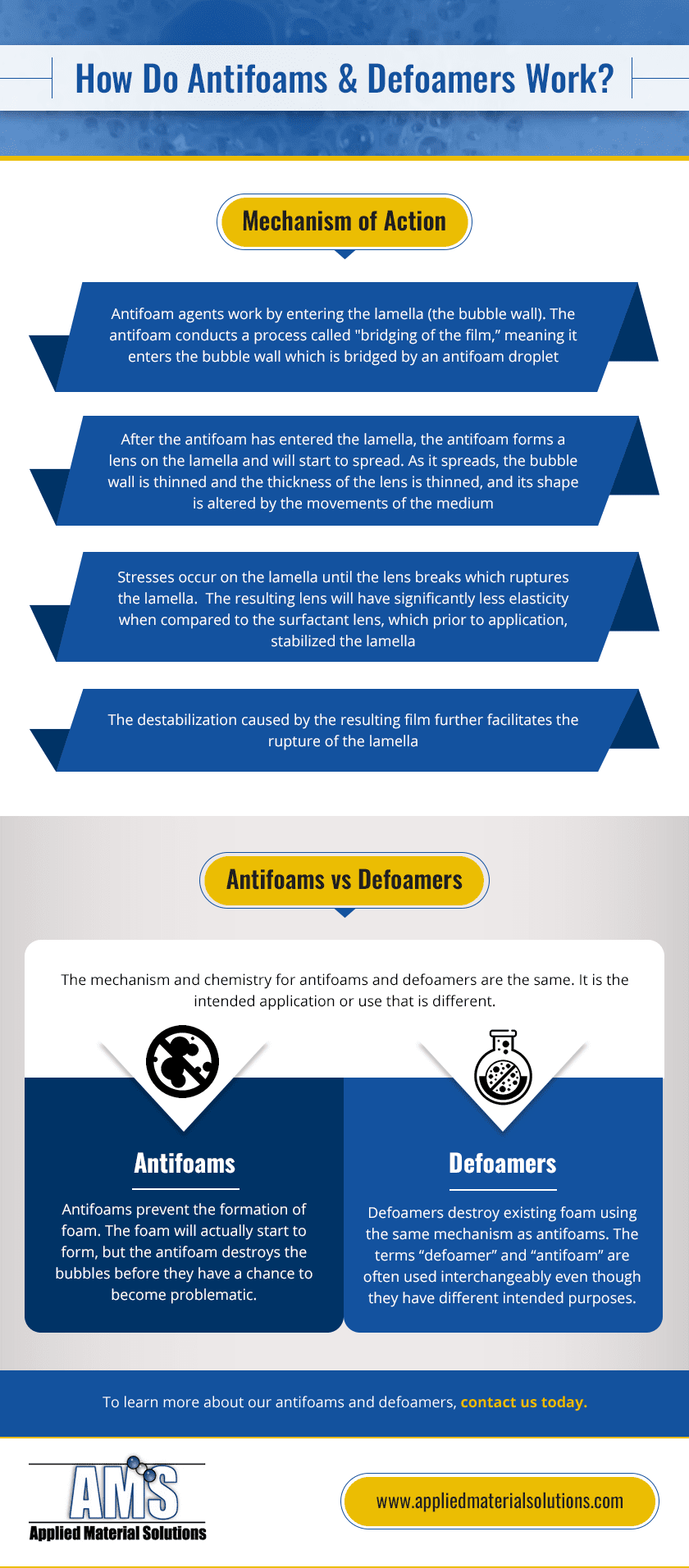

Defoamers play an essential function in numerous manufacturing processes by efficiently combating the formation of foam, which can affect and interfere with operations item high quality. Foam can emerge in countless contexts, such as during mixing, home heating, or chemical responses, possibly resulting in inefficiencies and variances in items. The mechanism through which defoamers operate commonly includes lowering the surface area stress of the fluid, permitting bubbles to coalesce and climb to the surface area quicker, where they can then rupture.

Reliable defoamers not just decrease foam development yet likewise keep compatibility with the product, ensuring that there are no damaging results on the final output. Understanding the properties and features of defoamers is essential for makers intending to maximize their procedures, boost productivity, and maintain the stability of their items (defoamers).

Key Benefits of Defoamers

Making use of defoamers in producing procedures provides a variety of significant benefits that enhance operational performance and product high quality. Among the primary advantages is the decrease of foam development during manufacturing, which can obstruct machinery and interrupt process. By minimizing foam, defoamers make certain smoother operations, causing lowered downtime and upkeep prices.

Additionally, defoamers enhance product consistency by protecting against air entrapment, which can endanger the integrity of the end product. This is particularly vital in sectors where aesthetic appearance and texture are critical, such as in paints, coverings, and food items. Enhanced product high quality not only meets customer expectations however also strengthens brand name track record.

Additionally, defoamers can help in optimizing resource use. By boosting the efficiency of basic material usage, they add to set you back savings and reduced waste, aligning with sustainability goals. Finally, the application of defoamers can bring about shorter processing times, making it possible for producers to boost production ability without significant capital expense - defoamers.

Applications in Various Industries

In making procedures across various sectors, the application of defoamers plays an essential role in improving efficiency and item high quality. These chemical ingredients are used in markets such as food and beverage, drugs, and fabrics to reduce foam-related obstacles.

In the food and beverage industry, defoamers are crucial throughout the fermentation process, protecting against lathering that can interfere with manufacturing and ruin the product's stability. Likewise, in the pharmaceutical market, defoamers are made use of in the formula of liquid medicines, making sure harmony and security while decreasing waste.

Fabric production additionally profits from defoamers, as they are made use of in coloring and ending up procedures to promote even circulation of dyes and chemicals. This application not just improves the final item's look however also reduces the amount of water and energy eaten during production.

Additionally, in the paper and pulp sector, defoamers help why not try these out keep procedure effectiveness by decreasing foam that can hinder machinery efficiency. Generally, the diverse applications of defoamers throughout these industries underscore their significance in optimizing production procedures and supplying high-quality products.

Choosing the Right Defoamer

Selecting a proper defoamer is vital for taking full advantage of effectiveness and top quality in manufacturing processes. The selection of defoamer relies on numerous factors, consisting of the particular application, the kind of foam being generated, and the formula of the item being produced.

To start with, take into consideration the chemical compatibility of the defoamer with other active ingredients in your formulation. A defoamer that engages negatively with other parts can negatively affect product quality. Furthermore, the temperature level and pH range during handling are vital; some defoamers do efficiently under specific problems while ending up being inadequate in others.

Second of all, assess the defoamer's efficiency qualities, such as its capability to rapidly decrease foam and its perseverance throughout production. It is important to pick a product that not only gets rid of foam rapidly yet likewise preserves its effectiveness gradually.

Finally, consider ecological and regulative variables, especially if your production process is subject to stringent conformity standards. Selecting a eco-friendly or low-toxicity defoamer can help fulfill sustainability goals while ensuring functional efficiency. By thoughtfully evaluating these criteria, producers can make enlightened choices that improve performance and product stability.

Finest Practices for Application

Effective execution of defoamers in manufacturing processes requires mindful preparation and adherence to ideal techniques. Picking the appropriate defoamer, as formerly reviewed, is critical; guarantee it is suitable with the products entailed and attends to the recognized frothing problems properly.

Following, preserve clear communication with all stakeholders, including operators and Read Full Report quality control teams. Training sessions can help ensure that everyone recognizes the application treatments, prospective effects on product top quality, and safety and security considerations. Carrying out a trial stage can likewise be valuable; display efficiency very closely to gauge effectiveness and make required modifications.

Furthermore, regular testing and surveillance of foam levels can provide beneficial understandings into the defoamer's efficiency gradually. Changing does in feedback to modifications in production variables will certainly assist keep ideal effectiveness - defoamers. Recording all processes and results advertises continual improvement, permitting for fine-tuning of defoamer use and improving general performance in producing procedures.

Final Thought

In recap, defoamers play a crucial function in enhancing effectiveness within manufacturing and manufacturing processes. By lessening foam formation and assisting in bubble coalescence, defoamers add to enhanced item quality, uniformity, and functional efficiency. Their application throughout numerous industries emphasizes their versatility and value in optimizing resource use and lowering processing times. Eventually, the critical implementation of defoamers makes it possible for manufacturers to boost manufacturing capacity efficiently, consequently fulfilling customer expectations and attaining expense savings.

The advantages extend to item quality and expense savings, as defoamers help enhance procedures.Defoamers play an important function in different making processes by properly combating the formation of foam, which can influence and interrupt procedures item high quality. Comprehending the properties and features of defoamers is important for suppliers intending to maximize their processes, improve performance, and keep the integrity of their products.

Making use of defoamers in manufacturing procedures uses an array of substantial advantages that enhance operational effectiveness and item top quality.In addition, defoamers enhance product uniformity see this site by protecting against air entrapment, which can endanger the stability of the final item.

Report this page